1942 - 1947 CHEVROLET SHOP MANUAL

Section 12 - Electrical System

|

|

|||

|

the opposite direction on the armature shaft. The

tension of the starter pedal

return spring holds the

pinion out of mesh with the flywheel while the

engine is operating.

DISASSEMBLY OF STARTING MOTOR

Before a starting motor is removed from an

engine, certain tests should be

made to be sure that the

starting motor is in need of repair. First check

the battery. If the specific

gravity is below 1.175, the

battery is discharged and should be recharged. Check the battery

ground connection at the frame and clean and tighten if necessary.

Check the battery

terminals. Dirty terminals result in poor connection

between the battery and the electrical units.

They should be cleaned regularly

and the battery washed off with a solution of bicarbonate of soda

and water.

Remove the starting

motor switch and check the

contacts to be sure that they are clean and not burned or

corroded. If after making the foregoing

inspections the starting motor

still does not function,

it should be removed and disassembled.

To disassemble-remove the starting motor

switch, commutator cover band,

through bolts and rear

housing. Remove the field coil to brush lead

machine screws and remove the

commutator end frame

assembly and then remove the armature.

To remove the drive

mechanism, first remove the bolt

on which the shift lever pivots and then remove

the shift lever and drive mechanism.

After the starting

motor has been completely disassembled. Fig. 44, wash all parts,

except the overrunning clutch, in

clean gasoline or cleaning solvent.

TESTING STARTING MOTOR PARTS

Field Coil Test for Continuous Circuit

|

12-21

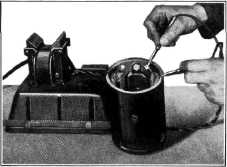

Place the test prod leads on the field coil leads,

Fig. 45. If the test lamp lights,

the field coils are OK. If

the test lamp does not light, there is an

open circuit in one or both of

the field coils.

Field Coil Test for Ground

|

||

|

|||

|

Fig. 46-Field Coil Test for Ground

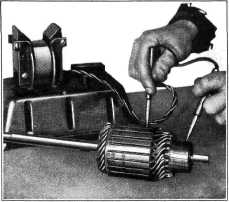

Place one test prod lead to frame and the other

to the field coil lead, Fig. 46.

If the test lamp does not light the field coils are OK. If the

test lamp lights, one or both

field coils are grounded.

Individual Field Coil Test for Ground

Break soldered

connection between the two field

coils and test each one separately replacing the

field coil found to be grounded.

Field Coil Leads

Inspect the field coil leads where they are soldered

at the starting switch terminal to be sure

that they are tight.

Armature Test for Ground

|

|||

|

|||

|

|||

|

|

|||

|

Fig. 45-Field Coil Test for Continuous Circuit

|

F!g. 47-Armature Test for Ground

|

||

|

|

|||