1942 - 1947 CHEVROLET SHOP MANUAL

Section 12 - Electrical System

|

|

|||

|

12-22

|

|||

|

|

|||

|

Place one test prod

on the armature and the other on the commutator, Fig. 47. If the test

lamp lights, the armature is grounded and should be replaced. If the

test lamp does not light, the armature is OK.

Armature Test for Short Circuit

|

Place one test prod

lead to the cover and the other on the brush holder, Fig. 49. If the

test lamp lights, brush holder is grounded and should be replaced. If

the test lamp does not light, the brush holder is OK.

Brushes

Check the condition of

the brushes and if they are pitted or worn, they should be replaced.

Check the tension of the brush holder springs; they should have enough

tension to hold the brushes snugly against the commutator.

Brush Ground Leads

Disconnect the brush

ground leads from the end frame and clean all terminals and replace.

Check the insulation of the brush to field coil leads. The insulation

should not be broken.

Drive Housing Bushing

Check the condition of

the drive housing bushing. The armature shaft should fit snugly in

this bushing; if it is worn it should be replaced.

REASSEMBLY OF STARTING MOTOR

Thread the shift lever

through the slot in the drive housing, while at the same time engaging

the bosses on the inner end of the lever in the sheave grooves on the

drive mechanism, then slide the lever and the drive into the housing

together, assemble the pivot bolt through the shift lever to the

housing.

Assemble commutator

end washer and commutator end frame assembly to the armature.

Assemble the armature and commutator end frame assembly to the

starting motor housing. Thread the armature shaft through the drive

mechanism, making sure to install the thrust washer between the drive

and the drive housing bushing. Install the through bolts and tighten

them securely.

Assemble the field

coil to brush lead machine screws. Oil commutator end frame bushing.

Connect the starting

motor to a battery and operate for running test. Assemble commutator

cover band and install the starting switch insulators in the switch

and assemble the switch to the motor. Replace starting motor on car

making sure all connections are clean and tight.

THE STARTING SWITCH

The starting switch

is designed to carry the heavy current required by the starting motor

without loss and without heating.

|

||

|

|||

|

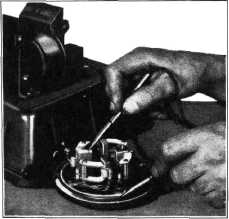

Fig. 48-Armature Test for Short

Place the armature on

the growler, and with a saw blade over the armature core, rotate the

armature and test, Fig. 48. If the saw blade does not vibrate, the

armature is OK. If the saw blade vibrates the armature is

short-circuited and should be replaced.

Commutator

Inspect the commutator

for roughness. If it is rough, turn down on a lathe until it is

thoroughly cleaned up, then sand off the commutator with 00 sand

paper.

Insulated Brush Holder Test for Ground

|

|||

|

|||

|

Fig. 49-Insulated Brush Holder Test for

Ground

|

|||

|

|

|||