1942 - 1947 CHEVROLET SHOP MANUAL

Section 12 - Electrical System

|

|

|||

|

12-23

|

|||

|

|

|||

|

The switch contacts are so arranged as to provide

a wedging action when contact is made thus

insuring a good connection, and

also giving the contacts a

wiping action which tends to keep them

clean.

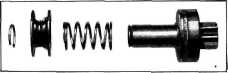

DRIVE MECHANISM

The drive pinion and over-running clutch is a

self-contained unit. If it becomes

damaged in any way the complete unit should be replaced.

However, should the spring be broken or the sheave

become worn, these parts may be

easily replaced by

compressing the spring to uncover the lock ring

|

reversing switch, through the switch to the distributor,

across the breaker points and back to the

grounded terminal of the reversing

switch, and back to the

negative terminal of the battery, Fig. 51.

|

||

|

|||

|

|||

|

Fig. 50-Starting Motor Drive Mechanism

in the tube part of the drive mechanism. Removal of the lock ring

permits removal and replacement

of both the sheave and spring. Fig. 50 shows a layout

of the drive mechanism parts.

THE IGNITION

SYSTEM

The power in a gasoline engine is derived from

the explosion of gas in the engine

cylinders. In order to

explode this gas, an electric spark is made to jump a small gap

inside the cylinder or combustion

chamber. The ignition system furnishes this spark. The spark

must occur in each cylinder at

exactly the proper time and the sparks in the various cylinders

must follow each other in the proper order or sequence. To accomplish

this, the following parts are

used: The battery which

furnishes the electrical energy; the ignition coil which transforms

the battery current to high tension

current which will jump the gap in the spark

plug; the mechanical breaker

which opens and closes the

primary circuit at the proper time; the distributor which delivers the

spark to the proper

cylinder; the spark plug which provides the gap

for the spark to jump in the

engine cylinder: the wiring

which connects the various units; the ignition

switch for disconnecting the battery when it is

desired to stop the engine.

OPERATION

When the ignition

switch is closed, current flows

from the battery positive to the starter switch, over

the wire to the ammeter and then

to the ignition switch,

through the switch to the coil. The current

now passes through the primary

winding to the

|

|||

|

Fig. 51-Ignition Circuit

|

|||

|

Current flowing through this circuit builds up a

magnetic field about the coil.

When the breaker points open, the current tends to keep on flowing

and surges into the condenser, attracting a positive

charge on one side and a negative

charge on the other. A

fraction of a second after the breaker points open, the counter

pressure in the condenser

overcomes the surge pressure on the line and the condenser discharges

from the positive charged side back through the primary winding of the

coil in the opposite

direction to the primary current, through the battery to the ground

and back to the grounded

side of the condenser, equalizing the two sides of the

condenser. The discharge current from the condenser, passing over the

primary winding tends to reverse

the polarity of the coil and results in a very rapid demagnetizing of

the coil. This rapid movement

of the lines of force across the large number

of turns of the secondary winding

induces a current of very

high voltage, which flows from the secondary winding to the high

tension terminal of the coil,

then to the distributor, across

the distributor rotor to

the spark plug, across the gap between the plug

points to the ground and back to

the other end of the

secondary winding, completing the circuit.

CONDENSER

The operation of the condenser is many times

misunderstood by the average

service man. It is one of

the most important units in the ignition system. In order to

understand its action and function, we will show a water analogy of

condenser action.

|

|||

|

|

|||