1942 - 1947 CHEVROLET SHOP MANUAL

Section 12 - Electrical System

|

|

|||

|

12-24

|

|||

|

|

|||

|

side of the condenser, which is grounded, equalizing

the two sides of the condenser. This is fundamentally the same

as when the counter air pressure

in the surge chamber of the water system, overcame

the surge pressure on the line. The surge chamber discharged and

forced the water back in the line equalizing the

pressure.

IGNITION DISTRIBUTOR

Since the spark must occur at a given instant

in the engine crankshaft rotation,

the switch must be operated

by the engine itself. This switch is

called the mechanical breaker,

timer or interrupter.

The breaker arm is pivoted at one end and carries

at its free end a contact which is held against

a similar contact by a spring

acting on the breaker arm.

The stationary contact is mounted on the

breaker plate to permit

adjustment of the points.

When the contact points are together and the ignition

switch is closed, current will flow through the breaker arm

contacts and primary winding of the

coil.

The cam is positively driven by the engine. As

it rotates, the lobes of the cam

strike the rubbing block

on the breaker arm, causing the arm to swing outward, thus

separating the contacts or points. This interrupts the current which

was flowing through the primary

winding of the coil, and produces a spark as previously described. As

the cam continues to turn, the lobe passes the rubbing block

and the spring pulls the breaker

arm back until the

contacts come together again. The current then

flows through the primary winding

of the coil and the

operation is repeated as before. The cam is not

only positively driven from the

engine, but it is also

"timed" to the engine so that it interrupts the

circuit through the coil at the

instant the spark is

required.

The mechanical breaker is made in this form in

order to open the primary circuit

quickly and to operate at

the highest speed.

AUTOMATIC SPARK CONTROL

The spark control is of the automatic type, that

is, the spark is automatically

advanced or retarded by two

methods. First, the vacuum spark control

gives quick advance to the spark,

to give power at low

engine speeds and when the throttle is

opened quickly the spark is

momentarily retarded,

preventing laboring of the engine and pinging, until the load is

relieved, at which time the spark is

automatically advanced. At higher

engine speeds, this vacuum spark control cuts out, retarding the

spark for better economy

and engine performance at

these higher speeds.

|

||

|

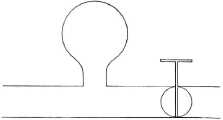

Fig. 52-High Pressure Water Line

In Fig. 52 we have a high pressure water line

with a valve located in the line.

Just ahead of the valve is

located an air chamber called a surge

chamber.

When the valve is opened, there is not a full

head of water, because it takes

some time to set a body of

water in motion. During this time energy is stored in this volume of

water, because of its speed

of movement. If the valve is suddenly closed

the pressure on the line plus the

momentum of the moving body

of water has to be stopped. This is

many times greater in pressure

than the normal line

pressure. The surge pressure forces the water

into the air chamber compressing

the air. The air then

offers a counter pressure which slows down the momentum of the

water. A moment later the air

pressure in the air chamber overcomes the surge

pressure in the line, and forces

the water back into the

line. This action absorbs the surge without

damage to the system.

The condenser in the ignition system, Fig. 51, acts in exactly the

same manner. When the ignition

switch is closed, it takes a fraction of a second

to establish the full current

value flowing in the

circuit, just the same as it required some time to

set the water in motion. When the

breaker points open the

current tends to keep on flowing, just the

same as the water tends to keep on

flowing after the valve is

closed. If there was no condenser, this

surge of current would arc across

the distributor points and

burn them, just the same as the velocity

of the water would carry away the

valve in the water line.

The current surges into the condenser attracting a positive charge on

one side and a negative

charge on the other, building up a counter

voltage in the condenser, just

the same as the water surging into the air chamber, compressing the

air, built up a counter pressure in the air chamber. A

fraction of a second after the

points open, the counter

pressure in the condenser overcomes the

surge pressure on the line, and

the condenser discharges

from the positively charged side back through the primary

winding of the coil, through the battery to the ground and back to the

negative

|

|||

|

|

|||