1942 - 1947 CHEVROLET SHOP MANUAL

Section 12 - Electrical System

|

|

|||

|

12-33

|

|||

|

|

|||

|

HEADLAMPS

The "Sealed Beam"

headlighting system is used on all passenger cars and trucks. These

lamps are designed so that the light source, the reflector, the lens

and the gasket are all assembled in one securely sealed unit, known

as the sealed beam unit. When the filament burns out or the lens

becomes damaged or broken, the entire sealed beam unit is thrown away

and a new one installed, thereby assuring maximum lighting efficiency

throughout the entire life of the car.

"Sealed Beam"

headlamps provide two separate and distinct beams, giving the maximum

amount of road illumination at all times.

1. A

country (upper) beam (bright lights) is

designed to illuminate the road

evenly for considerable

distance ahead of the car. This beam

is for use on the open highway

when no other vehicles are

approaching.

2. A

traffic (lower) beam is also provided and is

low enough on the left side to

avoid glare in the eyes of

the oncoming drivers. It is intended

for use on heavily traveled

highways and should always

be used well in advance of approaching

vehicles. This beam is designed

so that it does not throw

any dazzling light into the eyes of

the approaching driver under any

condition of car loading. At the same time the distribution

of light is such that the right

side of the road is

illuminated as far ahead as is practicable without causing glare on

curves.

The operation of the

headlights is simple, allowing the motorist to use either the country

(upper) or the traffic (lower) beam as traffic and road conditions

demand by the use of the conveniently located dimmer switch on the

left side of the toe-pan.

When the country

(upper) beams are lighted a red pilot bulb in the instrument cluster,

at the top of the speedometer, will be illuminated, making it

convenient for the driver to determine when the bright lights are on.

Never pass an approaching car with this red light burning. ALWAYS

SWITCH TO THE TRAFFIC

(LOWER) BEAM WELL IN

ADVANCE OF ONCOMING CARS.

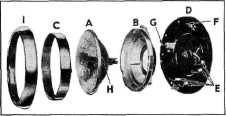

LAMP CONSTRUCTION

The sealed beam unit

(A) Fig. 69 is held to a sub-body

(B) by a retainer ring (C) and three screws which may be

loosened for removal of the unit. The sub-body forms a ball and socket

joint with a lamp housing (D) and is held to the housing by four coil

springs (E), plus the vertical adjustment screw (F), and the

horizontal adjust-

|

ment screw (G). With

this type of mounting the horizontal light beam adjustment can be made

without disturbing the vertical light beam setting and vice versa. The

sealed beam unit is provided with three locating lugs (H) which fit

into corresponding slots in the sub-body. These lugs are so located

that this unit can only be mounted in one position.

|

||

|

|||

|

Fig. 69-Sealed Beam Headlamp Parts

With this system

maintenance is greatly simplified, requiring only aiming of the beams

and the replacement of burned out or broken sealed beam

units.

Neither dust nor moisture can get at the

reflector because the entire unit is

sealed. The units

|

|||

|

|||

|

Fig. 70-Removing Headlamp Rim

|

|||

|

|

|||