1942 - 1947 CHEVROLET SHOP MANUAL

Section 2 - Frame

|

|

|||

|

2-12 |

|||

|

|

|||

|

apt to

become worn, causing oil leaks around the shaft. Such leaks can be

corrected only by replacing the

shock absorbers.

BROKEN OR INOPERATIVE SHOCK

ABSORBERS

Broken or

inoperative shock absorbers can readily be detected by lack of shock absorber

resistance or too much

resistance. Resistance may be checked as outlined under "To Check for

Fluid." Too much resistance may be caused by broken internal parts,

clogged valves or stuck pistons. No resistance may indicate lack of fluid, dirt holding valve

open, broken cam or other broken internal parts. Shock absorber may

be empty or low on fluid. Look for broken internal parts. Look for broken or

cracked shock absorber body. Broken or inoperative shock absorbers should be repaired or

replaced.

TO LOCATE SHOCK ABSORBER

NOISE

When noise blamed on shock

absorbers is encountered, there

are many points to be checked to determine the exact cause of the

noise.

Check for

worn or broken links or bushings; shock absorbers empty or low on fluid;

stabilizer links and bushings: hand brake parts; loose tools in car; broken internal shock absorber

parts; car spring shackles or

covers; loose sheet metal parts; loose bumpers; loose shock absorber

mounting, etc. All these can cause noise for which the shock

absorbers are sometimes blamed. If noise is definitely determined to be caused by shock absorber,

and cannot be corrected by external service, the unit should be removed for repair or

replacement. |

TO FILL WITH FLUID

ONLY

1. Clean the shock absorber thoroughly using a

stiff bristle brush and

kerosene for the purpose.

2. With fluid injector, J-1026, fill shock

absorber with G.M. Shock Insulating Fluid according to following instruction.

To Fill Single-Acting Shock Absorbers

1. (a) If shock absorber is equipped with a

filler

plug as

shown in Fig. 6, remove plug and fill

shock absorber to capacity.

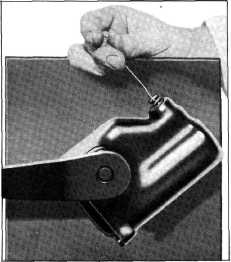

(b) If

shock absorber is not equipped with a filler plug, tilt unit to an angle of about

45° with arm end down. Remove

valve nut with a heavy

screwdriver, preferably of the offset type, Fig. 17. Remove relief valve,

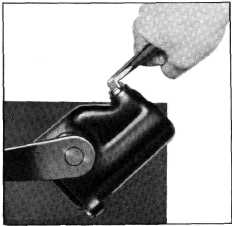

using & small

hooked tool or bent wire as shown in Fig. 18. Fill shock absorber to

capacity.

2. Replace filler plug, or relief valve and

nut. |

||

|

|||

|

|||

|

Fig. 18—Removing Shock Aborber Relief

Valve

3. Move arm up and down vigorously several

times to work the fluid into

the cylinder.

4. Remove plug or valve and add additional

fluid to fill reservoir to capacity if necessary.

5. Withdraw a quantity of fluid

equivalent to

about two

tablespoonfuls. 6. Replace filler

plug, or valve and nut, using a

new gasket. |

|||

|

Fig. 17-Removing Shock Absorber Filler

Plug |

|||

|

|

|||