1942 - 1947 CHEVROLET SHOP MANUAL

Section 4 - Rear Axle, Universal Joints & Springs

|

|

|||

|

4-14 |

|||

|

|

|||

|

Pinion

Disassembly

1. Clamp the rear yoke of the universal joint

in a bench vise and remove the

cotter pin, nut and washer from

the end of the pinion shaft.

The

universal joint rear yoke as well as the bearing retainer and oil seal may then be

removed from the pinion shaft.

2. To remove the rear pinion bearing, take off

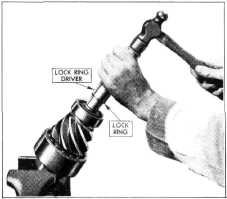

the lock ring and then using a

special press plate, J-1453.

press the pinion and shaft out of the bearing, Fig. 23.

NOTE—The raised portion of the

press plate must be against the inner race otherwise the bearing will be

damaged.

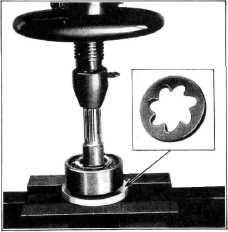

3. Install the front pinion bearing remover

J-1439 for 6 tooth pinion,

J-1440 for 7 tooth pinions, over the pinion teeth and against the inner

race of the double row pinion

bearing. Then press the bearing

off the pinion shaft, Fig. 24. |

2. Press the rear bearing on the end of the

shaft with the chamfered side

of the inner race toward the

pinion. Install the lock ring using the lock ring installer J-1364, Fig.

25.

3. Slide the pinion bearing retainer and oil

seal over the universal joint

yoke. If replacement of the oil

seal is necessary, install the felt packing toward the bottom of the recess and

then the oil seal with the open

end of the leather toward the

pinion bearing. The oil seal should be pressed, down against the felt

packing, Fig. 15.

NOTE—Soak a new leather oil

seal in light engine oil for at least one hour before

installing. |

||

|

|||

|

|||

|

Fig. 25—Rear Pinion Bearing Lock Ring Installer

4. Install the pinion bearing retainer gasket

and then slide the universal

joint yoke over the splines on

the pinion shaft until it contacts the inner race of the

bearing.

5. Place the flat washer on the end of the

pinion shaft and tighten the

nut down to a torque load of 160 to 280 ft. lbs. Lock the nut in place

with the cotter

pin.

Differential Disassembly

The

differential side bearings are a press fit on each side of the differential. To remove

these bearings, the special puller shown in Fig. 26 should be

assembled to the case with the

two fingers of the puller in

the two notches of the case. This allows the fingers to pull in against the inner

race of the bearing which will

prevent damage to the bearing. These bearings should never be removed in an

arbor press because removing

them in this way will damage the bearings so that they will be unfit for

further use.

After the

bearings have been removed, they should be washed in gasoline or cleaning

solvent |

|||

|

Fig. 24—Removing Front Pinion Bearing

Inspection

Wash all parts in clean gasoline

or cleaning solvent. Inspect the pinion for worn or chipped teeth.

Inspect the splines on the pinion shaft for wear or scoring. Oil the bearings and turn them

slowly by hand to check for roughness. Check the fit of the bearings in the carrier. These should be a

close push fit by hand. Inspect the oil seal in the pinion bearing retainer and replace with a new one

if necessary.

Pinion Reassembly

1. Press

the front double-row pinion bearing onto the pinion shaft with the extended portion

of the bearing inner race

against the back of the gear teeth. |

|||

|

|

|||