1942 - 1947 CHEVROLET SHOP MANUAL

Section 4 - Rear Axle, Universal Joints & Springs

|

|

|||

|

4-15 |

|||

|

|

|||

|

|

||

|

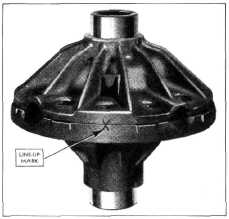

Fig. 27—Differential Case Line-Up Marks

NOTE—If any one of the

differential gears are damaged or scored all should be

replaced.

Reassembly

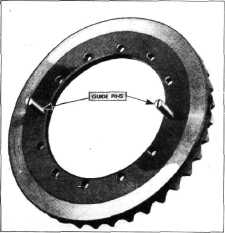

When

reassembling the differential, the flanges of the case, ring gear pilot and the back

of the ring gear must be clean

and free from burrs.

When

replacing the ring gear, it is good practice to use two guide pins made from

differential and ring gear

screw, part No. 3652253. Their ends should be slightly tapered and screwdriver

slots cut so they may be easily removed, Fig.

28. |

|||

|

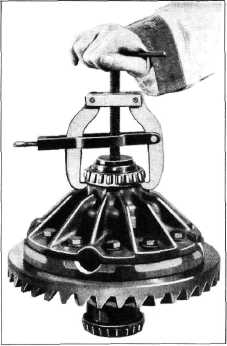

Fig. 26—DifferentiaI Bearing

Puller |

|||

|

and blown

out with clean air. They should then be oiled and rotated by hand, to check for

roughness.

To

disassemble the differential, check and make sure the case halves are

marked, Fig. 27, so it may be

reassembled in the same position. Remove the twelve 1/2" bolts from the case.

Lift off the case cover and

remove the differential gears and pinions.

The ring

gear may be removed from the right-hand side of the case by tapping it with a

soft-faced

hammer.

Inspection

Wash all

parts thoroughly in clean gasoline or cleaning solvent. Check all gears for

chipped, cracked or scored

teeth. Inspect the differential side gear and pinion thrust

surfaces in the housing halves for

wear or score marks. Check the fit of the side gear hubs in the differential case

halves. The fit of the pinions

should be checked on the spider. The differential side bearings should be

carefully inspected for worn,

checked, scored or broken rollers. They should then be oiled and

rotated by hand to check for

roughness.

Any damaged

or worn parts should be replaced. |

|||

|

|||

|

Fig 28—Guide Pins in Ring Gear |

|||

|

|

|||