1942 - 1947 CHEVROLET SHOP MANUAL

Section 4 - Rear Axle, Universal Joints & Springs

|

|

|||

|

4-20 |

|||

|

|

|||

|

When installing new bearing outer

races, use special driver J-1322 for front race, and J-1321 for rear

race—care should be exercised to press the races squarely and firmly

against their seats.

NOTE—The pinion cage as

serviced through the Parts Warehouse will come with the front and rear

pinion bearing outer races pressed into place.

The double reduction shaft left

bearing cap will be serviced with the outer race in place, because it

requires expensive tools to remove and replace the bearing outer

race.

The ring gear and pinion will be

serviced only in matched sets.

Reassembly

Lubricate the bearing roller

races. Install the rear pinion bearing on the drive pinion, install spacer

on shaft up against bearing. Install pinion, bearing and spacer in the

pinion cage. Then install over the pinion shaft, and up against the front

face of the spacer inside the cage, the same number and thickness shims as

removed. Press the front pinion bearing on the shaft until stopped; this

should produce a slight "drag" when turning the pinion cage. Should

the cage turn too freely, or too hard, remove the front bearing and

add or remove shims as necessary to produce the slight "drag," or proper

adjustment. Shims are available in .021", .024", .030" and .034". After

arriving at proper adjustment of pinion bearings, install

spring-loaded oil seal, with open end of leather to the rear, using a

driver to support front face of seal to prevent damage. Install joint

yoke, washer, nut and cotter pin.

Double Reduction

Shaft—Disassembly

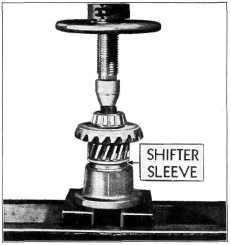

Remove the lock rings from the

bearing nuts. The nut at the end opposite the ring gear should be removed

first, to permit removal of the bearing, low-speed pinion, shifter

sleeve, and detent balls and springs. Then clamp the splined section of

the double reduction shaft in a vise equipped with copper jaws to protect

the teeth, and remove the bearing nut from the ring gear end of the

shaft.

Replace the shifter sleeve on the

shaft, allowing it to bear against the high-speed pinion. With the

assembly resting on the shifter sleeve supported in an arbor press, press

the bearing and ring gear from the shaft. Fig. 38.

Inspection

Clean all parts and inspect the

ring gear and double reduction pinions for cracked or chipped teeth. Check

the fit of the pinions on the shaft and inspect the bearings for damaged

rollers or cracked races. Any damaged parts should be replaced. Fig. 39

shows the parts which make up the double reduction shaft

assembly. |

Reassembly

Before installing the double

reduction pinions on the shaft, their inner bearing surfaces must be

thoroughly lubricated with rear axle lubricant for initial

lubrication. |

||

|

|||

|

Fig. 38—Removing Double Reduction Shaft Bearing on Ring Gear

End

Install the high-speed double

reduction pinion on the shaft with the spur gear side toward the spur gear

on the shaft. Start the ring gear on the splines. Then press the ring gear

on the shaft. During this operation use a feeler gauge to check the

clearance between the high speed double reduction pinion and the splines

on the shaft; a clearance of .015" to .020" (.015" or near this preferred)

must be allowed between these two parts to prevent scoring and to

allow proper shifter sleeve travel. Fig. 40. This clearance is controlled

by how far the ring gear is pressed on the shaft. |

|||

|

|||

|

Fig 39—Layout of Double Reduction Shaft Assembly

Start the roller bearing on the

shaft, and, using a sleeve over the shaft and against the bearing inner

race, press the bearing solidly against the ring

gear. |

|||

|

|

|||