1942 - 1947 CHEVROLET SHOP MANUAL

Section 4 - Rear Axle, Universal Joints & Springs

|

|

|||

|

4-24 |

|||

|

|

|||

|

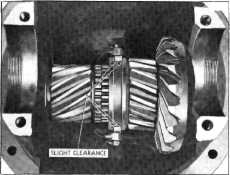

pinion

moves the tooth bearing towards the heel of the tooth, while insufficient backlash

moves the tooth bearing towards

the toe of the tooth.

To check

the backlash use a dial indicator on the heel of a ring gear tooth. Correct

backlash is from .006" to

.012", Fig. 48.

To adjust

the backlash proceed as follows:

If insufficient backlash—remove

the double reduction shaft bearing caps and remove a shim from the left side and add a shim of the same

thickness to the right side.

If the

backlash is excessive—remove a shim from the right side and add a shim of the

same thickness to the left side. Continue these adjustments until the backlash is within

limits. |

|

||

|

|||

|

Fig. 50—Axle Shift Lever and Stop Pins

made when disassembling. Tighten

the bearing cap bolts just

"snug."

Check the position of the double

reduction gears with the double reduction pinions. Move the differential by the adjusting nuts until the

double reduction gears line up with the double reduction pinions. Adjust the bearings by pulling the

adjusting nut up tight,

then backing it off one notch.

Tighten the

bearing cap bolts tight and install the adjusting nut locks and then lock all

bolts with tie

wire.

Install the

differential and carrier assembly in the axle housing, using a new gasket between

the housings.

Remove the

pipe plug in the pinion cage and with

a lubricating gun, fill the space between the pinion bearings with one pint of

lubricant.

NOTE—It will not be necessary

for any further lubrication at this point while the truck is in

service.

Assemble

the axle shafts using new aluminum gaskets. Install the capscrew locks and

capscrews, tightening them

securely.

Complete

the reassembly by connecting the rear universal joint. Fill the rear axle housing

with 14 pints of S.A.E. 90

Mineral Oil Lubricant, "All Purpose" or "Universal" gear

lubricant.

Lubrication

Use S.A.E. 90 Mineral Oil

Lubricant, "All Purpose" or

"Universal" Gear Lubricant. However, it is important that the proper viscosity be

selected to match the seasonal

temperatures. While S.A.E. 90

will provide satisfactory year around

lubrica- |

|||

|

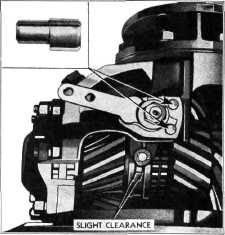

Fig. 49—Shifter Sleeve Yoke Shoe Clearance in

Sleeve

To check

the movement of the shifter sleeve, and yoke shoe clearance in the sleeve, move

the shifter lever to the high-speed position and make sure the side of the sleeve is flush up

against the side of the

high-speed pinion. In this position the sleeve yoke shoes should have a

slight side clearance on

both sides in the sleeve recess, Fig. 49. Move the shifter lever to the low-speed

position and make the same

yoke shoe clearance check with the shifter sleeve flush up against the snap

ring on the low-speed pinion.

Any

necessary adjustments to produce proper shifter sleeve travel or yoke shoe

clearance in the sleeve recess

can be made by turning the shifter lever stop pins, Fig. 50, which are

eccentric, with a large pair of

pliers. A groove in the stop pin indicates the low side of the

eccentric.

Lubricate

the differential bearings, assemble the outer races, and install the assembly in

the carrier. Then assemble the

adjusting nuts and caps, using the capscrews as a guide to line up the

adjusting nuts. Make sure the

cap and adjusting nuts are installed according to the center punch

marks |

|||

|

|

|||