1942 - 1947 CHEVROLET SHOP MANUAL

Section 4 - Rear Axle, Universal Joints & Springs

|

|

|||

|

4-25 |

|||

|

|

|||

|

tion in most sections, there are

some sections where extremely low

temperatures are encountered during the winter months. In such

sections it is advisable to add

10% to 20% kerosene.

During the summer months in

sections where the temperature is

very high and the truck is subject to severe service conditions, a heavier

grade of lubricant such as

S.A.E. 140 may be used.

It is not

necessary to change the lubricant with the seasonal changes, however, it is

recommended that the housing

be drained, flushed, and refilled twice a year, or approximately every 6,000

to 10,000

miles.

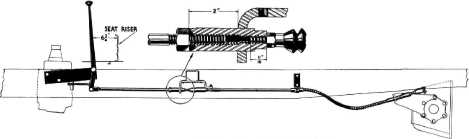

SHIFTER MECHANISM AND

ADJUSTMENTS

The shifter

lever on the rear axle is controlled by a hand lever in the cab of the truck and

is connected by rod and

cable linkage to the shifter lever at the rear axle.

The

installation of the control linkage on the various trucks varies somewhat due to the

difference in Wheelbase. However, the adjustments are the same on all units. Fig. 51 illustrates

the installation.

Adjustments

1. Check all brackets and U-bolts on the frame

to make sure they are in their

proper position. The brackets

are staked and the cable housings are grooved for the

U-bolts.

2. Shift the shifting lever on the axle

differential carrier to the

fully forward position (low ratio). Disconnect the cable clevis from the

shifting

lever.

3. Disconnect the front adjustable pull rod at

the front end clevis.

4. Loosen the check nut at the back end of the

sleeve passing through the

front support bracket. Unscrew

the sleeve and front adjustable pull rod assembly from the front end

of the second pull rod, just ahead of the rubber boot. |

5. Using a scale on the threaded section at

the front end of the second pull rod, adjust the check nut to allow exactly 11/16" of this

threaded section to extend

forward of the nut —measuring

from the front flat surface of the nut to the front end of the rod, Fig.

51.

6. Loosen the check nut where the rear end of

the front adjustable pull rod

joins the sleeve. Screw the sleeve and front pull rod assembly

back onto the front end of the

rear pull rod. being careful

not to turn the rear pull rod check nut or upset the 11/16" measurement.

Lock sleeve onto front end of

rear pull rod by tightening check nut.

7. Set the shift lever in the cab so that it

is 6-3/4" from the rear

edge of the lever to the front of the seat riser as shown in Fig.

51.

8. Adjust the sleeve in the front support

bracket so that it extends 2"

forward of the support-measuring from the front face of the support to the

front end of the sleeve. While holding the sleeve in this measured

position, and the front pull

rod check nut loose, adjust the pull rod as necessary, by screwing it in or out

of the sleeve, until the front

end clevis pin hole lines up

with the hole in the bottom of the shift lever to allow installation of the

pin— the shift lever in the

cab during this adjustment must be set as outlined in paragraph

7. Insert pin and tighten check nut at front end of

sleeve.

9. At the shift lever on the differential

carrier, make sure the lever is

still in the fully forward position—low ratio, and detent ball seated.

Then adjust the clevis at the

cable end so the hole in the

clevis lines up with the hole in the lever. Insert pin and tighten check

nut.

10. Shift

the hand lever forward and check to

make sure

that the lever on the differential

case is in

the full rear position or high ratio,

with the

ball in the detent.

The cable linkage is lubricated

at the lubrication

fittings

in the connectors. |

||

|

|

|||

|

|||

|

|

|||

|

Fig. 51—Two-Speed Rear Axle Shifter

Mechanism |

|||

|

|

|||