1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-18 |

|||

|

|

|||

|

The

connecting rod and piston should be assembled in the cylinder bore with

the piston pin clamp bolt on the

camshaft side of the engine.

Lubricate

either the piston or the cylinder bore and slip the pistons into the bores, using

extreme care. Do not force the rings into the bore. Compress the rings with the piston inserter,

J-975, and slip the assembly

into the bore until the chamfer on the inserter enters the chamfer at the

top of the cylinder bore, Fig.

9. With the inserter in this position, the piston rings will readily

enter the bore.

Lubricate

the crankpin and pull the connecting rod down onto it, making sure that

the numbered side of the rod is

toward the camshaft. Install three .002" shims on each connecting rod

bolt and then install the

bearing cap with the numbered side toward the camshaft. Install the

connecting rod oil dipper with

its open side toward the camshaft. Assemble and tighten the

nuts.

Adjusting Connecting Rod Bearings

Remove

shims, an equal number from each side of the bearing, until the rod cannot

be snapped forward and backward on

the crank pin by hand, but can

be tapped back and forth with a light blow of an 8 ounce hammer. Then place one

.002" shim on one side, being careful to keep the number of shims on each side equal, if possible.

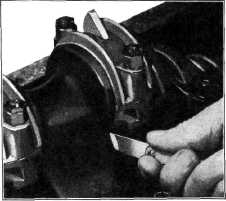

When the bearing is properly

fitted, it should be possible to snap the rod back and forth on the crank

pin with one hand, Fig,

35. |

of the

crankpin with a feeler gauge. This clearance should not be less than .004" nor more

than .011", Fig.

36. |

||

|

|||

|

Fig. 36—Checking Connecting Rod End Clearance

Lock the

connecting rod bolt nuts by installing new "pal" nuts. The "pal" nuts must be

installed with the open side of

the nut toward the end of the bolt. Turn the "pal" nut up finger tight and

then 1/2 turn

more.

As a final

and last check to be sure that the piston and rod assembly will travel true

with the bore, check the

clearance between the piston pin end of the connecting rod and the piston

pin bosses on the piston with

a feeler gauge This should not

be less than .025".

ENGINE OILING SYSTEM

Engine

lubrication is supplied by a positive driven gear pump equipped with a spring

loaded by-pass valve to control

the maximum pressure at high

speeds and when the engine oil is heavy and sluggish during cold weather

starting.

The engine oiling system provides

positive pressure lubrication to

the main bearings and camshaft bearings. The connecting rod

bearings are lubricated at low speeds

by means of dippers on the rod

bearing caps which dip into oil filled troughs in the oil pan. At high speeds

lubrication is amply maintained by oil nozzles. Cylinder walls

and pistons are lubricated by the oil

spray thrown off by the connecting rods. Lubrication of the valve

mechanism is accomplished by oil

being pumped to the hollow

rocker arm shafts.

MAIN AND CAMSHAFT BEARING

LUBRICATION

The oil flow is from the pan,

through the pump screen and oil pump

to the block fitting, and then |

|||

|

|||

|

Fig. 35—Checking Connecting Rod Bearing

Fit

If it is not possible to keep the

number of shims equal on each side

for all bearings, it is preferable to have the greater number of shims on

the camshaft side.

Check

connecting rod end clearance between the upper half of the connecting rod and the

side |

|||

|

|

|||