1942 - 1947 CHEVROLET SHOP MANUAL

Section 7 - Transmission

|

|

|||

|

7-7 |

|||

|

|

|||

|

2. Blow out the bearings with compressed

air.

CAUTIONóDo not allow the

bearings to spin, but turn them slowly by hand. Spinning bearings

will damage the races and balls.

3. After making sure the hearings arc clean,

lubricate with light

engine oil and check them for wear or roughness. Roughness may be

determined by slowly

turning the outer race by hand

Transmission Case

Wash the

transmission case inside and outside with gasoline or cleaning solvent and

inspect for cracks. Inspect

the front face which fits against clutch housing for burrs and if any are

present, dress them off with a

fine cut mill file.

Gears

1. Inspect all gears and, if necessary, replace

any that are worn or damaged.

2. Check the first and reverse sliding gear to

make sure it slides freely on

the clutch sleeve.

3. Check the clutch sleeve to see that it

slides freely on the

mainshaft.

4. Check the synchronizing cones for wear or

for being loose in the clutch

sleeve. If the cones are damaged in any way, it will be necessary to

replace the clutch sleeve

assembly and both synchronizing rings.

Synchronizer Rings

1. Inspect the synchronizer rings for

smoothness.

2. Place the synchronizer rings in the

synchronizing cones and

check with the thumbs to see that the rings do not rock.

Excessive

rocking indicates a poor fit between the ring and cone, which will not permit

proper synchronizing of the gears during shifting.

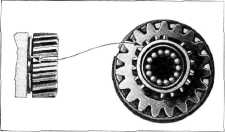

Synchronizer Energizing Springs

1. It will be noticed upon examining these

springs that one of the ends

is slightly offset. Each spring must be assembled in its groove in

the clutch gear and the second

speed gear with the offset or

locking end between the third and fourth teeth of either of the two banks of

teeth on these gears, thus keeping the spring from turning in its groove, Fig. 10. The gap in

the spring must not be in line

with the opening between

either bank of teeth on either gear mentioned.

2. Under normal operation it should never be

necessary to replace the

energizing springs; however, should an energizing spring be removed

for any reason, a new spring

should be installed. |

|

||

|

Fig. 10óCorrect Position of Energizing Spring

The spring

may be removed by slipping a thin blade under the spring and raising it

over the clutch teeth on the gear and

slipping it off over

the

teeth.

CAUTIONóIn replacing either

energizing spring, be very careful not to distort the spring when

expanding it over the clutch teeth.

Bushings

1. The

bushings used in the countergear and the idler gear are pressed into the gears, then

peened into holes in the bores,

to lock them in place, and are accurately bored with special

diamond boring tools. This

insures the positive alignment of the bushings and their shafts as

well as the proper meshing of the

gears. Because of the high

degree of accuracy to which these parts are machined the bushings are not

serviced separately, but

as a part of the gear assembly. |

|||

|

|||

|

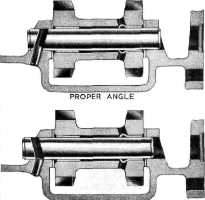

WRONG ANGLE |

|||

|

Fig. 11óReverse Idler Gear, Shaft and Lock

Pin |

|||

|

|

|||