1942 - 1947 CHEVROLET SHOP MANUAL

Section 7 - Transmission

|

|

|||

|

7-8 |

|||

|

|

|||

|

2. Check the bushings for

excessive wear by using a narrow feeler gauge between the shaft and the

bushings. The proper clearance is from .002" to

.004". |

of the shaft engages the clutch

housing when the transmission is installed in the chassis, and keeps the

countershaft from turning. This flat must be horizontal and at the top or

the transmission cannot be assembled to the clutch

housing.

NOTE—The step at the end of the

countershaft should be flush with the front face of the case, or

approximately 1 64" below the face, to maintain proper transmission

alignment.

Rear Bearing

1. Install the rear bearing lock ring in the

case.

2. Start the bearing in from the rear, and use

the lock ring expanding tool,

J-935, to expand the ring into

the case.

3. Using a soft steel drift, tap the bearing on

the outer race until it is in

about halfway; then remove the

lock ring expanding tool and continue to tap the bearing until the lock

ring seats in the groove in the

bearing.

Synchronizing Clutch Sleeve Assembly

1. Install the synchronizer ring retainers in

the counterbores in the ends of

the clutch sleeve.

2. With the special pliers. J-932. expand the

retainer, at the same

time holding it flush with the

back face of the cone. Install the synchronizer rings, making sure that the retainers

seat in the groove all the way

around the rings. Fig.

S.

3. Install the first and reverse sliding gear

on the clutch

sleeve.

4. Install the second speed gear in the rear

end of the clutch sleeve,

meshing the clutch teeth on the

gear with the internal teeth in the clutch sleeve.

5. Coat the grooved side of the second speed

gear thrustwasher with transmission lubricant and place the washer on the back face of the

second-speed gear. Then

install the clutch gear assembly in the transmission

case.

Mainshaft

1. For initial lubrication, place

transmission lubricant on the second-speed gear bearing area of the

mainshaft. When installing the mainshaft, the lugs on the front

synchronizer must slide through the slots in the mainshaft spline. Push

the shaft into the clutch sleeve as far as possible by hand, picking

up the second-speed gear and thrustwasher. |

||

|

REASSEMBLY |

|||

|

Reverse Idler |

|||

|

1. Lubricate the reverse idler gear

thrustwashers and install the

gear and thrustwashers in the case with the gear having the chamfered

teeth to the rear of the

case.

2. Install the idler shaft, making sure that

the lock pin hole in the shaft

lines up with the hole in the

case at the same angle, Fig. 11.

CAUTION—A pin punch should be

used to make sure that these holes line up, for if the lock pin is driven

into the case and shaft with the hole in the shaft at the wrong angle

serious damage will result.

3. Use a new idler shaft lock pin and drive it

in approximately 1/16" beyond

Hush with the case, and peen

the hole slightly. This lock pin must be a tight fit in the case to prevent oil

leaks.

4. Install the idler shaft expansion plug in

the case.

Countergear

1. Install the countergear in the case;

lubricate the forward thrust

washer and install it between the countergear and

case.

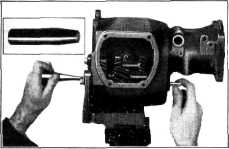

2. Feed the assembly tool, K-386, in from the

front, picking up the forward

thrustwasher and

countergear.

3. Lubricate the rear thrustwasher and slip it

between the countergear and

case, picking it up with the

assembly tool.

4. Lubricate the countershaft and install it

from the front, pushing the

assembly tool out with the

shaft. Fig. 12. The flat on the forward end |

|||

|

|||

|

Fig. 12—Countershaft Assembly

Tools |

|||

|

|

|||