|

ROCHESTER CARBURETORS Bulletin 9D-9 January 1952 |

|||||||

|

Page 16

ROCHESTER PRODUCTS, DIVISION OF

GENERAL MOTORS, ROCHESTER, NEW YORK

FLOAT BOWL ASSEMBLY |

|||||||

|

|

|||||||

|

1. Place bowl and throttle body assembly in an

upright position on bench

or mounting block.

2. Install pump inlet filter screen

and retainer in the bottom of

the float bowl.

3. Install aluminum pump inlet ball in pump

well and brass pump outlet

needle in pump discharge passage,

located beneath primary venturi cluster. |

|

||||||

|

PUMP RETURN S |

||||||

|

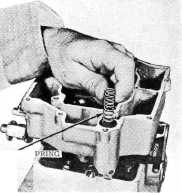

Figure 7-20 |

|||||||

|

4. |

Install the pump return spring in

pump well and position by compressing with finger. (Figure

7-20.)

Install both main metering jets on

the secondary or fuel inlet side of the carburetor. Be certain the proper

jets (last two digits of part number stamped on jet) are

installed.

Place venturi cluster gasket in

position on fuel inlet side of carburetor. Be certain all gasket

holes are properly aligned. |

||||||

|

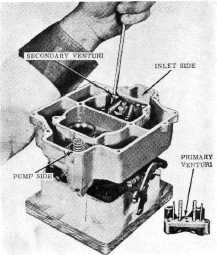

MAIN METERING JETS |

||||||

|

9. |

Figure 7-21

Install secondary venturi cluster

on fuel inlet side of carburetor with three retaining screws and lock

washers. (Figure 7-21) This cluster has no pump discharge

nozzles.

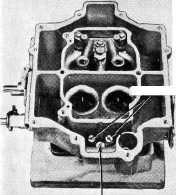

Install (he fiber gasket and power

valve assembly on the pump (Primary) side of the carburetor.

(Figure 7-22.)

Install both main metering jets on

the primary or pump side of the carburetor. Be certain the proper jets

(last two digits of part number stamped on jet) are installed. (Figure

7-22.) |

||||||

|

|

|||||||

|

POWER VALVE Figure

7-22 |

|||||||

|

|

|||||||