1942 - 1947 CHEVROLET SHOP MANUAL

Section 3 - Front Suspension, Axle & Springs

|

|

|||

|

Section

3 |

|||

|

|

|||

|

KNEE ACTION OR INDEPENDENT FRONT WHEEL

SUSPENSION

PASSENGER CAR MODELS |

|||

|

|

|||

|

CONSTRUCTION

The 1942 passenger car front

wheels are independently sprung

by the S. L. A. (short and long arms) method.

This

design allows the wheel to move straight up or down in following irregularities of

the road. Whether these irregularities be raised obstructions or chuck holes, the shock will not be

transmitted to the car or

passengers.

In this

construction the complete assembly is attached to an unusually large and rugged

frame front cross member of

box section construction which

is rigidly bolted to the frame side rails, Fig. 1. This cross member is also

reinforced by a bracket under

each side rail. The brackets are riveted to the cross member and bolted to

the frame side rails. This construction facilitates complete overhaul or replacement in that the

complete assembly may be

removed from the frame as a unit.

Chassis

coil springs 14-1/8" long are employed which are mounted in seats, one seat

attached to the lower control arms and the other being in the frame front cross

member.

Double

acting shock absorbers of the parallel cylinder type are rigidly bolted to the top

of the frame front cross

member. The front and rear upper control arms are permanently attached

to the shock absorber shaft to

provide great strength and resistance to shock. The two upper arms

are electrically welded together.

Each lower control arm is pivoted at its inner end on a forged

shaft attached to the underside of the frame front cross member by two brackets forged integral with

the shaft (see Fig- 10). Each

control arm carries a hardened steel bushing of the thread bearing

type. Neoprene seals cover the inner

end of each bushing and the

threads on the shaft. These seals prevent dirt and water from

entering the bearings, thereby prolonging their life.

The

steering knuckle support, which carries the steering knuckle and kingpin, is pivoted at

its upper and lower ends to the upper and lower control arms.

At the lower end a steel threaded type bushing is screwed into the

steering knuckle support. A

threaded bolt which passes through both arms and the bushing completes the

mounting. Neoprene seals

protect the bearing from road dirt |

and water.

The upper end of the knuckle support is mounted to the upper control arms through

threaded bushings and a

threaded eccentric bolt which

provides for caster and camber adjustments.

The

steering knuckle is of the reverse Elliott type, pivoting on the kingpin through

floating bushings which permit

movement of the bushings on

the kingpin as well as in the steering knuckle. Two tie rods are

used which connect directly to the

pitman arm—the right-hand tie rod is solid while the left tie rod is adjustable to

provide for toe-in

adjustment.

Rubber

bumpers for rebound and compression are mounted on the frame front cross member

and lower spring seats. The lower (or compression) bumper engages the underside of the front

cross member and the upper (or

rebound) bumper engages

the upper support arm at the point where the two arms are welded

together.

A front-end stabilizer is used in

connection with this suspension to

provide steering stability and control of body roll. The stabilizer is a

long steel bar attached to the

under side of the frame side rails ahead of the cross member by

rubber bushed brackets. Delco type

connector links are used to connect the stabilizer bar to the coil

spring seats on the lower control arms. The linkage provides complete rubber insulation between the

metal parts. |

||

|

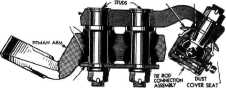

DUST COVER

PACKING |

|||

FORGED PLATE RUBBER

BUSHINGS |

|||

|

RETAINER PLATE

Fig. 2—Pitman Arm and Ball

and Socket Joint Assembly

The ball

and socket joints on the tie rod connections are of the self adjusting type,

protected from dirt and water by a dust cover and packing. This construction is shown in Fig. 2 at the

end that connects to the

pitman arm and in Fig. 17 at the tie rod end.

The pitman

arm is a built-up assembly (Fig. 2).

The pitman arm proper is a heavy forging machined to receive tapered rubber bushings.

The |

|||

|

|

|||