1942 - 1947 CHEVROLET SHOP MANUAL

Section 3 - Front Suspension, Axle & Springs

|

|

|||

|

3-8 |

|||

|

|

|||

|

less than 3/32" op more than 1/4",

parts responsible (knuckle arm, pitman arm, short tie rod ends or

long tie rod) must be replaced as necessary to bring this space within the

limits, 3/32" to 1/4". Wear on the tapered section of the ball stud

or hole in arm to decrease this space below 3/32" could only

be caused by running a considerable period with the ball stud nut

loose.

FRONT SUSPENSION ALIGNMENT

Front

suspension alignment is the mechanics of adjusting all the inter-related factors,

such as caster, camber, and

toe-in, etc., affecting steering. Incorrect adjustment of these factors may

result in hard steering, car

wander, shimmy, and abnormal tire wear. Complete information on

front wheel alignment

principles as well as the importance of each angle and adjustment is given later in

this section.

PRELIMINARY INSPECTIONS

Before checking the alignment of

the front suspension inspect the following, making necessary

adjustments or corrections:

1. TIRE MOUNTING-Check rim run-out and

eccentricity.

2. TIRE PRESSURE—Check and set to

recommended pressures for

the tires being used.

3. FRONT WHEEL BEARINGS-Check

for

looseness.

4. KINGPIN BUSHINGS-Check for

looseness.

5. STEERING GEAR-Check mounting bolts for

tightness.

6. STEERING CONNECTIONS-Inspect ball

and socket joints for

tightness.

After completing the above and

making any necessary adjustments, the front suspension

may |

be checked

on any reputable front end alignment

equipment.

In discussing the checking and

correction of alignment in this Shop Manual, we have selected for

illustrative purposes equipment that is in general use.

When placing the car on the front

end machine be sure that the front wheels are centered on the turntables

and that the front and rear wheels are parallel to the sides of the

runways. The rear wheels should be blocked to make certain the car will

not shift its position.

The front suspension is built as a

unit which includes the front cross member. The alignment of this unit is

adjusted at the factory with a fixed load applied to the assembly which

results in a given height from the top of the cross member to the center

line of the spindle. This is equivalent to a certain frame height when the

assembly is installed on the car.

The alignment specifications are

based on this normal frame height. Therefore, it is necessary that the

frame height at the front be set in this normal position in order to

duplicate the ORIGINAL FACTORY

SETTING CONDITIONS.

The alignment will vary with

different loads and operating conditions, but when set as above the

variation in caster, camber and toe-in will be within limits

necessary for satisfactory operation.

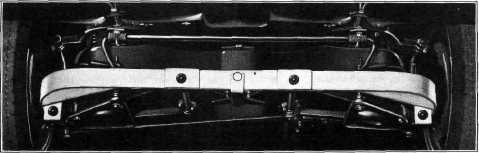

To locate the frame to the proper

height, install the approved gauge on the front. When installing the

height gauge, place the two center holes of the gauge over the lower

support arm shaft bushings; then raise or lower the front of the car by

the bumper until the sockets in the ends of the gauge fit over the hex

head of the lower pivot pins. Then install the clamp which locks the gauge

to the front cross member, Fig. 18. |

||

|

|

|||

|

|||

|

|

|||

|

Fig. 18—Position of Height Gauge at Front of

Car |

|||

|

|

|||