1942 - 1947 CHEVROLET SHOP MANUAL

Section 5 - Brakes

|

|

||||

|

5-1 |

||||

|

|

||||

|

Section

5

HYDRAULIC BRAKES |

||||

|

|

||||

|

The braking system of all 1942

passenger cars and trucks combines hydraulically operated service

brakes with mechanically operated emergency brakes. Fundamentally, the

braking system of the passenger cars and trucks is the same. However, due

to the variance in the brake lining sizes, wheel brake drum sizes, and

frame design there are several differences in the braking systems.

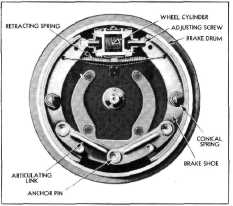

Fig. 1 shows the brake construction. |

the piston into the space between

the primary cup and the check valve, keeping sufficient fluid in the lines at all times. The holes in the valve

cage allow the fluid to flow through the cage and around the lip of

the rubber valve cup and out into the lines during the brake application.

When the brake is released the lip of the rubber valve cup seals the holes

in the valve cage and the valve is forced off its seat, permitting the

fluid to return to the main cylinder. The push rod assembly is held in the

opposite end of the housing by means of a snap ring. The rubber boot that

fits around the push rod and over the end of the housing prevents dirt or

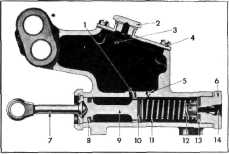

any other foreign matter from entering the main cylinder. Fig.

2. |

|||

|

||||

|

||||

|

Fig- 1—Front Brake Mechanism

In order to thoroughly understand

the operation of the hydraulic brake system, it is necessary to have a

good knowledge of the various parts and their functions and to know what

takes place throughout the system during the application and release of

the brakes.

MAIN CYLINDER

The piston in the main cylinder,

Fig. 2, receives mechanical pressure from the push rod and exerts pressure

on the fluid in the lines, building up the hydraulic pressure which moves

the wheel cylinder pistons. The primary cup is held against the piston by

the piston return spring which also retains the return valve against its

seat. The spring maintains a slight pressure in the lines and in the wheel

cylinders to prevent the possible entrance of air into the system. The

secondary cup, which is secured to the opposite end of the piston,

prevents the leakage of fluid into the rubber boot. The holes in the

piston head are for the purpose of allowing the fluid to flow from the

annular space around |

||||

|

Fig. 2—Main Cylinder Cross

Section |

||||

|

1 Inlet

2 Filler

Plug

3

Reservoir

4 Housing

Cover

5 Compensating

Port

6 End

Plug

7 Push Rod |

8 Piston

Cup—Secondary

9 Piston

10 Piston Cup—Primary

11 Spring

12 Valve

13 Valve Seat

14 Outlet |

|||

|

WHEEL CYLINDER

The wheel cylinder, Fig. 1, is a

double piston cylinder, the purpose of the two pistons being to distribute

the pressure evenly to each of the two brake shoes. The rubber piston cups

maintain pressure on the pistons and prevent the leakage of fluid

past the pistons. The adjusting covers serve two purposes: first, to cover

the ends of the cylinder and prevent the entrance of dirt and foreign

matter into the cylinder, and second, serve as a means of adjusting the

brake shoes to the proper drum clearance, being threaded to receive the

slotted adjusting screws which fit the webs of the brake

shoes. |

||||

|

|

||||