1942 - 1947 CHEVROLET SHOP MANUAL

Section 5 - Brakes

|

|

|||

|

5-2 |

|||

|

|

|||

|

SEQUENCE OF EVENTS

DURING

APPLICATION AND

RELEASE

OF

BRAKES

As

pressure is applied to the brake pedal and is transmitted from the push rod to the

piston in the main cylinder,

the primary cup closes the compensating port and fluid is forced

through the holes in the valve

cage, around the lip of the rubber valve cup, into the pipe lines and into the

wheel cylinders. This pressure

forces the pistons in the wheel

cylinders outward, expanding the brake shoes against the drums. As the pedal is

farther depressed, higher

pressure is built up within the hydraulic system, causing the brake shoes to

exert greater force against

the brake drums, Fig. 1.

As the

pedal is released, the hydraulic pressure is relieved and the brake shoe

retracting springs draw the shoes

together, pressing the wheel cylinder pistons inward and forcing the fluid

out of the wheel cylinders back

into the lines toward the main

cylinder. The piston return spring in the main cylinder returns the piston to the

pedal stop faster than the

brake fluid is forced back into the lines, creating a partial vacuum in that

part of the cylinder ahead of

the piston. This vacuum causes a small amount of fluid to flow

through the holes in the piston head,

past the lip of the primary cup and into the forward part of the cylinder.

This action keeps the cylinder filled with fluid at all times, ready for the next brake application.

As fluid is drawn from the

space behind the piston head it is replenished from the reservoir through

the inlet or breather port.

When the piston is in a fully

released position, the primary cup clears the compensating port, allowing excess fluid to

flow from the cylinder into the

reservoir as the brake shoe

retracting springs force the fluid out of the wheel cylinders.

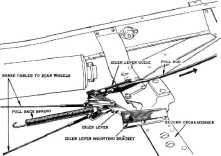

EMERGENCY BRAKE

The passenger car emergency brake

lever is located under the dash

on the left of the steering column and is connected to the idler lever

with rod-type linkage. The

idler lever is mounted in two

brackets riveted to the center of the second frame cross member. Two one-piece cables are

pivoted at the center of the

idler lever and are attached

to the rear brakes.

The pull

rod from the control lever is yoked at one end of the idler lever and provides

proper torque for emergency brake application, Fig.

3.

SERVICE OPERATIONS

To

properly maintain the braking system, servicemen must appreciate that a thorough

knowl- |

edge of the

system, absolute cleanliness, and careful workmanship are very

important. Absolute cleanliness is

necessary because any foreign matter in the system will tend to

clog the lines, ruin the rubber cups

of the wheel and main cylinders, and cause inefficient operation or even failure

of the |

||

|

|||

|

Fig. 3—Emergency Brake Linkage |

|||

|

braking

system; dirt or grease on a brake lining will cause that lining to take effect first

on brake application and fade

out on heavy brake application. Careful workmanship will result in a

well done

job.

BLEEDING THE HYDRAULIC BRAKE SYSTEM

The

hydraulic brake system must be bled whenever a pipe line has been disconnected,

when a leak has allowed air to

enter the system or at any time the system has been opened. A leak

in the system may sometimes be

evident through the presence of a "spongy" brake pedal. Air trapped in the

system is compressible, and

does not permit all pressure applied to the brake pedal to be

transmitted through to the

brake shoes. The system must be absolutely free from air at

all times.

The longest

pipe line of the brake system should be bled first. The proper sequence

for bleeding is: left rear, left

front, right rear, and lastly, right front. During bleeding operations the main

cylinder must be kept at

least half full of hydraulic brake fluid. The main cylinder filler,

J-713-C, Fig. 4. automatically

maintains the correct fluid level in the main cylinder during

bleeding.

TO BLEED THE HYDRAULIC BRAKE SYSTEM

Carefully

clean all dirt from around the main cylinder filler plug.

Remove

filler plug, install adapter and automatic filler. Open automatic valve in the

filler.

Remove

bleeder valve screw. Attach bleeder drain, Fig. 5, keeping the end of the drain

hose below the surface of the fluid in the

jar. |

|||

|

|

|||