1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-16 |

|||

|

|

|||

|

This can

be done with the dial indicator as shown in Fig. 30. The face and rim of the

flywheel should not

exceed .008" run-out.

CONNECTING RODS

Chevrolet

connecting rods are made of special steel, drop forged and of unusual strength.

The connecting rod bearings are of the "spun-in" type. By this is meant

that the babbitt lining or bearing part is an integral part of the rod

assembly. The metal is not

simply poured or die cast into place. Instead, the rod and cap forgings are

clamped to a special face plate

which revolves at a high rate of speed. The centrifugal action set up

causes the molten metal to be

forced out towards the walls of

the rod, and, in cooling becomes practically a part of the connecting

rod.

The connecting rods are then

checked for alignment, weighed and go through a series of other important dimension checks. The rods that

pass this very careful inspection are then placed in new engines or

sent out for service.

Every time a connecting rod is

removed and is |

to be

replaced in an engine, or a new connecting rod is to be installed, it should be

carefully checked for alignment

on a connecting rod alignment fixture.

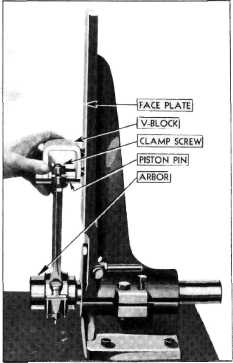

Connecting Rod Alignment

The

connecting rod alignment fixture, Fig. 31. is used to accurately check the alignment of

the piston and pin with the connecting rod bearing.

The

connecting rod is clamped on the arbor, as shown in the illustration, and by use of

the "V" block resting against

either the piston or the piston pin, the amount of misalignment will be

shown between the pins on the

"V" block and the face plate

on the fixture.

To check

the rod on this fixture, place the pin in the rod and assemble the rod and pin to

the arbor on the fixture. Place

the "V" block on the piston

pin, and move the rod and arbor toward the face plate. The vertical pins will

indicate a cocked or bent rod.

By that it is meant that if the two top pins rest against the face plate and

the two bottom pins are away

from the face plate, the rod is

cocked or bent. The same is true if the two bottom pins rest against the face plate and

the two top pins are away from

it.

If the two horizontal pins, on the

front side, rest against the face

plate and the two hack pins are away from it, the rod is twisted. The same

is true if the two back pins

rest against the face plate and the two front pins are away from the face

plate.

The fixture is sufficiently strong

to hold the connecting rod, if

straightening is necessary, which can be done with a bending

bar.

After this

check has been made and the rod straightened, if necessary, so that all

four pins touch the face

plate, the "V" block should be placed on the piston pin so that the "V"

block rests against the

outside edge of the connecting rod and then the rod and "V" block is moved toward

the face plate until all four

pins touch. The index, on the

bottom of the fixture, is then placed so that it touches the large end of the connecting rod

bearing. Remove the rod

from the arbor and turn it around. Assemble it again to the arbor and

place the "V" block on the piston pin in the same place as when checking the other side. Move rod

and "V" block toward the face

plate until either the index

touches the bearing or the pins touch the face plate. If the index does not touch the

rod bearing with the four pins touching the face plate, the distance between the rod bearing and the

index should be checked with a feeler gauge. If this distance is more than .025" the rod should be

straightened until both the

pins touch the face plate and

the index touches the rod bearing, within .025". |

||

|

|||

|

Fig. 31—Connecting Rod Alignment

Fixture |

|||

|

|

|||