1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

||||

|

6-17 |

||||

|

|

||||

|

If the

index touches the rod bearing and the

four pins do not touch the

face plate, the distance

between the pins and the face

plate should also be checked

with a feeler gauge. If this

distance is more than

.025" the rod should be

straightened until the

pins, on the "V" block,

touch the face plate and

the index touches the

rod bearing within.

025".

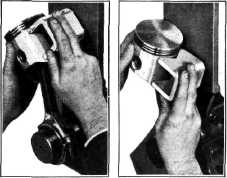

Assembling Connecting Rod

to Piston

Place the piston in a piston vise.

Fig. 32. Assemble the rod to the

|

make this

check, the connecting rod and piston assembly is mounted on the alignment

fixture and the piston is set in line

with the connecting rod. Then

place the "V" block on the piston skirt. If both pins on the block contact

the face plate the rod is not

cocked. Fig. 33. Then, with the "V" block on the piston skirt and the pins

against the face plate, tip the piston first in one direction and

then in the other, Fig. 34. If the

pins on the block |

||

|

||||

|

Fig. 32—Assembling Connecting Rod

to Piston |

piston and

install the |

|||

|

pin. Before tightening clamp screw, center the piston pin in the

piston and the rod in the center of the two piston pin bosses. Tighten the clamp screw and move

piston on the pin from side to

side, checking to see that the

piston pin does not extend beyond the outside of the piston.

NOTE—The connecting rod should

never be clamped in a bench vise when installing the piston on it as

tightening the clomp screw will likely twist the rod.

Assemble

the piston and connecting rod

assembly to the

align |

||||

|

Fig. 34—Checking Piston and

Connecting Rod Assembly for Twisted Connecting Rod

remain

against the face plate, there is no twist in the connecting rod. But if one pin leaves

the face plate while the

piston is being tipped in one direction and the other pin

leaves the face plate while the piston

is being tipped in the other direction, the connecting rod is twisted and should be

straightened until both pins follow the face plate.

Assembling Piston and

Connecting Rod to Engine

In production, both the connecting

rod and the bearing cap are stamped on

the camshaft side with the number of the cylinder in which they are

to be assembled. When the rods are

being reassembled they should be replaced in the same cylinder from

which they were removed with the

stamped numbers on the camshaft side.

The

condition of the crank pins on the crankshaft should be checked when installing new

rods. Damaged crankpins can

only be corrected by the installation of a new crankshaft, as it is

impossible to insure connecting

rod bearing life on a damaged crankpin.

The gaps

in the three piston rings should not be in line, one above the other. Stagger

the gaps so that they will be equally spaced around the piston but

so that there is no ring gap directly over the piston pin end. Gaps in this

position will allow gases to

leak by at this point. |

||||

|

ment

fixture, Fig. 33, and check with the

"V" block resting against the

piston skirt to see that

the rod and piston are

in alignment. Both pins

on the "V" block should

rest against the face of

the plate on the fixture.

The piston should be in

the same alignment as

the connecting rod when

this check is

made.

A quick

check of a |

|||

|

Fig. 33—Checking Piston end

Connecting Rod Assembly |

piston and

connecting |

|||

|

rod

assembly for both |

||||

|

cock and

twist can be made without

disassembling the rod from the piston. This method saves considerable time

on any repair operation that

does not normally require

the removal of the rod from the piston. To |

||||

|

|

||||