1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-23 |

|||

|

|

|||

|

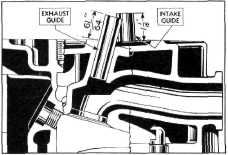

The

clearances that must be maintained between the intake valve stem and guide is

.001" to .003", and the

clearance between the exhaust valve stem and guide is .002" to

.004".

Quite

naturally, if the valve guides are worn they should be replaced. To remove them

from the cylinder head, the

driver shown in Fig. 47 must be used. Place the cylinder head in an arbor

press and press the guide from

it using this tool.

The valve

guides do not have a shoulder to determine the distance they should be pressed

into the cylinder head. The intake guides should extend above the cylinder head 1-1/16" while the

exhaust guides extend above

the head 61/64". These dimensions are very important, Fig.

48.

To simplify

this operation and make sure the valve guides are pressed in the proper

distance, two valve guide

drivers are available. These drivers contain stop collars to

automatically stop the guides at the proper height.

After the

guides have been pressed into the cylinder head, they should be rough

reamed with a .341" reamer and then

finish reamed with a .343"

reamer. |

|

||

|

Fig. 49—Valve Spring Tension Gauge

of an engine are reconditioned or

ground, the valve springs should be checked to be sure they have not been weakened from the heat of the engine.

This can easily be done by placing the valve spring in the valve

tester, U15, Fig. 49. and compressing it to a length of 1-1/2". At this length

the spring tension should be from 125 to 133 pounds. Springs that

do not test within these limits

should be replaced with new

genuine Chevrolet valve springs. |

|||

|

|

|||

|

|

||

|

|

|||

|

Fig. 48—Valve Guides

Valves and valve guides used on

the 1942 engines are interchangeable

with those on 1941 engines BUT

NOT WITH ANY MODELS PRIOR TO 1941.

VALVE SPRINGS, CAPS AND COVERS

Genuine

Chevrolet valve springs are made from a special analysis steel wire. They are

accurately coiled, and, after

being made, each spring is checked to insure that it is within the-

limits for tension. Springs

that fail to pass this inspection are immediately

scrapped.

Weak valve

springs affect the economy and power

of the engine; therefore, each time the

valves |

Fig. 50—Valve Spring Compressor

Each valve

spring is retained to the valve with a

cap and key. It is necessary to compress the spring with the spring compressor. Fig. 50,

which is a part of the cylinder

head holding fixture, far enough to allow the keys to be inserted

around the valve

stem.

The valve springs are assembled

with the close coiled end against the

cylinder head.

NOTE—Due to the difference in

the recess depth, the round valve spring caps must be installed on

the intake valves and the hexagonal caps on the exhaust valves. The intake

valve spring cap covers must be installed on the ends of all intake valve

stems. |

||

|

|

|||