1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

||||

|

6-22 |

||||

|

|

||||

|

tion. Bend pipe on right side of

block to clear the push rod cover. Then bend the upper portion of pipe to pass through the hole in the

cylinder head. Connect the pipe to the valve rocker shaft coupling.

Fill the cooling system with water, start the engine and check all

connections for both oil and water leaks.

CYLINDER HEAD ASSEMBLY

One of the most important units of

any valve-in-head engine is the cylinder head. It contains not only the

combustion chambers and spark plugs but the valves, inlets ports, exhaust

ports and the necessary water passages to maintain the proper temperature

of these important parts.

The Chevrolet cylinder head is

designed to give a compression ratio of 6.50 to 1 and 90 horsepower (the

same head giving 6.62 to 1 ratio and 93 horsepower on the heavy duty

235.5 cubic inch engine.)

The combustion chamber is designed

for use with a flat top piston that provides exceptionally compact

combustion volume on the exhaust valve side where the spark plug is

located.

On the intake valve side the head

is machined so that, except for a shallow recess in which the intake valve

is located, the bottom face of the head over the piston is flat and is

separated from the piston at top dead center by the thickness of the

cylinder head gasket only.

The valves are so located that

they permit the incoming charge of fuel mixture to enter the combustion chamber, do its work, and leave the

chamber after its work is done, without restriction, making use of

the volume of mixture efficiently with the least possible

disturbance.

This type

cylinder |

VALVES

Chevrolet valves have a high

resistance to heat, corrosion and pitting. They are made from sili-chrome

stainless steel by what is known as an extruding process. This

manufacturing process is a development of Chevrolet and it shapes the

rough valve in one operation.

From the rough forging to the

finished product all operations are carefully performed and

inspections are frequent.

The end of the valve stems are

hardened electrically to reduce wear at the contact point with the

rocker arm.

Valve Guides

The clearance between the valve

guides and the valve stems is very important. Lack of power and noisy

valves, in many instances, can be traced to worn valve

guides.

The intake valve guides should be

checked with a new intake valve and the exhaust guides with a new exhaust

valve, because the diameters of the stems are different on these

parts.

The exhaust valve guide is

designed to bring the inner end of the guide flush with the inside of the

valve port. With this design the heat dissipating properties are increased

and aids in eliminating sticking valves. |

|||

|

||||

|

head is the

result of many years' experience

in providing ample

water space around the

valves and spark plugs in

addition to a means for most

effective distribution of

water. The coldest water is

taken |

|

|||

|

into the cylinder head and

directed toward the |

Fig. 46—Cylinder Head Water

Nozzles |

|||

|

valve seats by means of

•

eight small copper nozzles pressed

into the lower part of the head. There are three kinds of these nozzles

used—long and short type, each with a single opening used to direct single

streams of water to the single exhaust valves at the end cylinders

and another with two openings which direct two streams of water to the

other exhaust valves, Fig. 46. |

||||

|

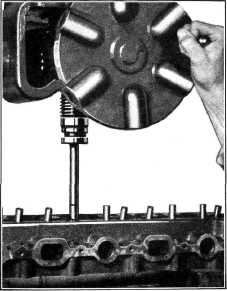

Fig. 47—Removing Valve Guide |

||||

|

|

||||