1942 - 1947 CHEVROLET SHOP MANUAL

Section 9 - Steering Gear Assembly

|

|

|||

|

9-6 |

|||

|

|

|||

|

The

tension of the horn blowing ring, or load required on the ring to blow the horn, may be

adjusted by removing the

ornamental cap in the center of

the steering wheel, and turning the screws shown in Fig. 13, as

necessary. |

worm is welded integral to the

wormshaft as shown in Fig. 14. The

steering wheel is attached to the upper end of the wormshaft. The

worm is mounted between two barrel

type roller bearings, the lower one of which is adjustable toward

the upper, for removing end-play in the wormshaft. Between the roller

bearings, the worm is threaded with a precision-finished helical

groove.

The ball

nut is bored to clear the outside diameter of the worm as shown in

Fig. 15, and the bore is threaded

with a precision-finished helical groove corresponding to that in the worm. Within

the length of the nut the

helical grooves are filled with special steel balls of 9/32" diameter

(made to specifications specially drawn up for this steering gear).

There are two complete ball

circuits in the nut. To complete each circuit and keep the balls

from running out at the ends,

the nut is fitted with two tubular ball guides, each of which deflects

the balls from their helical

path when they reach the end of

the nut, returning them to the helical path in the nut at the start

of the circuit.

The two

ball guides, together with the helical grooves in the worm and nut. thus confine

the balls within two distinct

closed circuits, one in each end of the nut. The balls within the helical

path, 30 in each circuit, constitute a thread between the worm and

nut, so that when the worm is turned, the nut moves along the worm, as with an ordinary

screw thread. At the same time

the balls roll freely between

the worm and nut, circulating within their closed circuits, so that screw motion is

obtained with rolling instead

of sliding contact between the parts.

Rugged

rack teeth are cut in that portion of the nut which faces the sector as shown in Fig.

14.

The sector

shaft is mounted in anti-friction bronze bushings. A grease seal is provided

near the outer end of the sector shaft. The sector is provided

with rugged teeth which mesh

with the rack teeth of the nut.

These teeth are not ordinary spur gear teeth, but are produced by a special process

to provide true gear

action between the rack and sector when the nut is located at a slight angle.

With this construction, the adjustment for back-lash between the rack and sector teeth is very simple—all

that is required is to shift

the sector shaft slightly along its own axis by means of a convenient thrust

screw, known as a lash

adjuster.

The sector

teeth are purposely cut in such a way that, when the sector is adjusted to remove

all back-lash at the

straight-ahead position of the front wheels, there will be a slight

back-lash at each end of the

sector travel, or when the wheels are turned far to the right or left of

straight-ahead. In this way

snugness of the sector in the rack teeth can be maintained with the

wheels in |

||

|

|||

|

Fig. 13—Horn Blowing Ring Tension Adjustment

Turning the screws clockwise

increases the tension, and

counterclockwise reduces it.

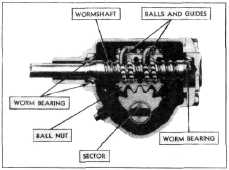

STEERING GEAR ASSEMBLY

CONSTRUCTION ALL CONVENTIONAL

TRUCKS

The truck steering gear, Fig. 14,

is of the recir-culating ball type. Steering gear ratio on all

conventional truck models is 19.8 to 1. |

|||

|

|||

|

Fig. 14—Truck Steering Gear Worm. Nut and Ball

Circuits

The

principle working parts are the steering worm, the ball nut and the sector and

shaft. Each of these parts is

of heat-treated alloy steel. The |

|||

|

|

|||