1942 - 1947 CHEVROLET SHOP MANUAL

Section 3 - Front Suspension, Axle & Springs

|

|

|||

|

3-19 |

|||

|

|

|||

|

driven out

by inserting a bar through the hub so that one end rests against the cup. By

tapping lightly at several

points around the circumference of the cup, through notches in shoulder

inside of hub, it can be removed without damage. It is well to remember that the cups are very hard,

therefore, extreme care

should be used in removing not to crack them.

In

replacing the cups, be sure that they are pressed into the hubs evenly and

as far as they will go, that is, that

their backs are against the shoulder in the bottom of the

hole.

Before

installing the separator and ball assemblies in the hub they should be packed with

grease. Use a high melting point front wheel bearing grease on all passenger cars and conventional

trucks, and a soft smooth

grease on C.O.E, models. (Fibrous or viscous type lubricants must not be used.)

DO NOT put grease into the

hubs, as such excess grease is

not required and simply increases the chances of leakage into the brakes.

CAUTION—The necessity of

removing the bearing cups is usually due to damage to the

ball race in the cups,

in which event, the only, remedy is a new

part.

When

replacing the front wheel be sure the inner oil deflector is in its proper place

between the inner bearing cone

and the shoulder on the knuckle spindle. As the wheel is pushed

onto the spindle it should be made certain that the inner oil deflector has passed inside of the outer oil

deflector.

Be sure

that the nuts which hold the wheel to the wheel hub are put on with the taper

side to the wheel

hub.

ADJUSTING FRONT WHEEL BEARINGS

After the

wheel has been installed on the steering knuckle spindle, with the bearings and

felt retainer in their proper

location, install the spindle washer against the cone of the outer

bearing then adjust the

bearings as follows:—

1. Using an 8" wrench (never larger) and

applying a steady force

with one hand, pull up the adjusting nut until the wheel is somewhat

hard to turn by hand. At the

same time rotate the wheel to

be sure that all parts are correctly seated.

2. Back off the adjusting nut one-half

castellation or one-twelfth

turn.

3. If the slot in the nut and the cotter pin

hole line up, insert the

cotter pin. If not, back the nut off until the slot and the hole are in

line and then insert the cotter

pin.

NOTE—In order to provide for

close bearing adjustment, the cotter pin hole is drilled in the spindle in

both the vertical and horizontal plane. |

With the

bearing inner cup an easy-push fit in the hub and the nut a free-running fit on

the spindle threads, this will give an adjustment toward the tight side, which will allow for

settling and working-in of the

parts in service.

Front

wheel bearings should never be set up on the loose side, as such an adjustment does

not bring the balls and races into proper contact.

It is well

to note that the slight friction of a new snugly fitting felt retainer assembly

will temporarily produce

a slight drag on the wheel, but this is easily recognized and need not be

confused with adjustment of

the bearing. Spin the wheel, making sure that all parts are in correct

position, then clinch cotter pin securely.

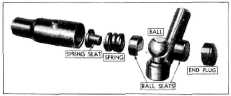

FRONT AXLE TIE ROD

The front

axle tie rod is of the ball, seat and spring type, similar to the steering

connecting rod construction.

Refer to

Fig. 43, and note how parts are assembled. The parts on both ends are

assembled in the same manner.

First the spring seat, then the spring and ball seat, then the ball and

ball seat, and then the plug.

Ball seats should be assembled so that notches line up with ball

neck.

To properly

adjust this front axle tie rod:

1. Remove cotter pins.

2. Screw plugs in tight until springs are

compressed solid and back

off to first cotter pin hole.

3. Insert and clinch cotter

pins.

4. Lubricate both ends of tie

rod.

To remove

the tic rod from the front axle, remove the cotter pin, end plug and ball seat.

Screw end plug back into the

end of the tie rod until the ball is in the center of the opening. A

light tap with a soft hammer

will remove the tic rod from the ball. |

||

|

|||

|

Fig. 43-Front Axle Tie Rod

1/2-TON PANEL TRUCK STABILIZER

A ride

stabilizer is used at the front of the 1/2-Ton Panel Truck to prevent excessive

sidesway on turns. The design is similar to that of the

passenger car models, the

major difference being in the changes necessary to adapt it to the

conventional front

axle. |

|||

|

|

|||