1942 - 1947 CHEVROLET SHOP MANUAL

Section 3 - Front Suspension, Axle & Springs

|

|

|||

|

3-20 |

|||

|

|

|||

|

To remove

the stabilizer from the truck, first remove the spring "U" bolts attaching it to

the top of the spring and then

remove the large bolt at the

upper end of the two-piece bracket which extends through the bracket, spacer, and

frame side rail. The

stabilizer assembly can then be taken from the car. To remove the bracket from the

bar it is necessary to remove

the bolts holding the two-piece

bracket together so as to relieve the pressure on the rubber bushings. The bracket and

bushing can then be slipped

off over the end of the bar.

Replacing

the stabilizer on the truck is the reverse of the above, except that the bolts

which clamp the two parts of

the bracket together should not be tightened until after the stabilizer

is in place on the truck, and

the weight of the truck with no pay load on its wheels. This is important so

that the rubber bushings will

grip the bar in proper relation to the frame and axle, and prevent

excessive up and down

movement of one front wheel relative to the other.

CAUTION-Do not attempt to

adjust the stabilizer by tightening the bolts in the bracket when

there is a load in the truck. This would destroy its

effectiveness.

All commercial frame front cross

members are punched for the adaptation

of this assembly if desired.

REMOVING AND INSTALLING

KINGPIN

To remove

and replace the kingpin, jack up the

front of the truck and remove the front wheel. Remove the nuts which attach the brake

flange plate to the steering

knuckle. Remove the brake flange plate. Remove the top kingpin

bearing plug. This can be done

with a sharp prick punch. Remove the kingpin lock

pin.

Drive the

kingpin down and out of the bottom with a brass rod. This removes the bottom

plug and the

kingpin. |

In

replacing the kingpin the operations are just the reverse of the above removal operations,

except that you should always use new kingpin bearing plugs and new

lock washers, and clinch over all cotter pins securely.

The kingpin bearing plugs on all

trucks except at the top of the kingpins on C.O.E, models, have no "expansion" feature, and must be staked in

place by peening or staking over the ends of the steering knuckle to hold the plugs securely in

place.

Drive in

the kingpin with a soft head hammer. After the kingpin is installed with the

thrust bearing assembled

at the bottom of the kingpin with the dust shield side at the top, check the

clearance between the steering

knuckle and axle "I" beam, Fig. 44. If this clearance is more than

.006" install a steel shim between the steering knuckle and the "I" beam at the top of the

kingpin.

In

installing this shim, start the kingpin in at the top of the knuckle and place the shim

over the kingpin. Mount the knuckle over the end of the "I" beam and drive the kingpin part way

through the "I" beam. Insert

bearing between the "I" beam and the knuckle and drive the kingpin into

position.

Due to the difference in design

between the Cab-Over-Engine and the conventional truck front axle, kingpin replacement is slightly different on

the C.O.E., and should be performed as follows after raising the

front end of the truck and removing the wheel and hub.

Remove the

turning radius stop bolt to provide wrench clearance. Remove the four brake

flange plate to steering

knuckle bolts and remove the flange plate

assembly. |

||

|

|||

|

|||

|

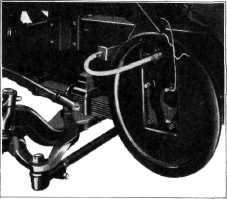

Fig. 45-C.O.E. Brake Flange

Plate Wired Up to Protect Brake Hose

NOTE—In order to protect the

brake hose while performing the following operations, the

flange |

|||

|

Fig. 44—Clearance Between Steering Knuckle and "I"

Beam |

|||

|

|

|||