1942 - 1947 CHEVROLET SHOP MANUAL

Section 4 - Rear Axle, Universal Joints & Springs

|

|

|||

|

4-27 |

|||

|

|

|||

|

|

||

|

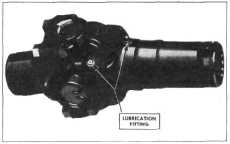

Fig. 53—Truck Intermediate Universal Joint

opening is sealed by a cork

packing contained in a retainer cap

which screws on the end of the yoke, Fig. 58.

Propeller Shaft Disassembly

1. Remove the nuts from the trunnion bearing

"U" clamps and remove the

clamps. (This may be done at

either or both the transmission end and/or the rear axle end depending

upon the amount of disassembly

desired.)

2. Unscrew the oil seal retainer from the rear

yoke of the intermediate, or

center, universal joint.

3. Remove the rear propeller shaft from the

front propeller shaft by

slipping it out of the universal joint splines.

4. Split the front universal joint at the

transmission end of the

front propeller shaft.

5. Remove the two bolts which mount the

intermediate universal

joint support bracket to the frame cross member.

6. Disconnect the intermediate universal joint

by removing the two trunnion

bearing "U" clamps.

NOTE—To hold the trunnion

bearings in place as well as to prevent dirt entering and save time in

reassembling, leave the bearings in the trunnion and tape them in

place.

7. Clamp one side of the front yoke of the

intermediate universal in a bench vise and remove the retaining nut with a 1-1/2"

socket wrench.

8. Using a soft hammer for the purpose, tap the

yoke from the propeller

shaft.

9. Wet the rubber cushion located in the

support bracket with water to

soften the soap used on the

rubber when assembled. Mount the support bracket in a bench

vise and move the propeller shaft

from side to side to work the rubber cushion out of the

support.

10. After the support bracket

has been removed |

|||

|

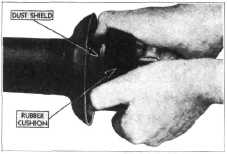

Fig. 54—Removing or Replacing Searing Rubber

Cushion

the

rubber cushion can be removed from the bearing with the hands as shown in

Fig. 54.

11. Mount the special puller, J-1619, in a

bench vise and fit the jaws of

the puller in behind the

bearing outer race. Turning the screw of the puller will remove the bearing from the

shaft, Fig.

55.

12. Tap the dust shields off the outer race of

the bearing. Fig. 56 shows a

layout of the parts making up the intermediate support bearing

assembly.

Inspection

Thoroughly

wash all parts. EXCEPT THE SUPPORT

BEARING, in clean gasoline or cleaning solvent. Inspect the shaft for worn

splines and replace shafts if

necessary. Check the bearing for roughness or excessive play by holding the

inner race with one hand while

slowly turning the outer race

with the other. If either condition is present, replace the

bearing. |

|||

|

|||

|

Fig. 55—Removing Propeller Shaft Intermediate

Bearing

NOTE—The intermediate support

bearing is of the permanently lubricated and sealed type, therefore no

attempt should be made to wash it out with gasoline or to re-lubricate

it.

Propeller Shaft Reassembly

1. Press

the outer dust shields on the outer race of the support

bearing. |

|||

|

|

|||