1942 - 1947 CHEVROLET SHOP MANUAL

Section 6 - Engine

|

|

|||

|

6-55 |

|||

|

|

|||

|

clutch

attaching bolts one turn at a time (to prevent cover distortion) until the

diaphragm spring pressure is

released.

5. Remove

the three clutch pressure plate retracting springs, then remove the pressure

plate from the clutch cover assembly, Fig. 112. Note the position of the "O" marks on the

pressure plate and cover.

These must be matched when reassembling in order to maintain proper

balance.

NOTE—For ease of servicing,

the clutch cover, diaphragm spring and two pivot rings are built up as an

assembly. If inspection shows that there is a defect in any of these parts

it will be necessary to replace the complete cover

assembly.

Inspection

The first

step in connection with inspection of the clutch is to wash all parts

(except the throwout bearing and

disc) in clean gasoline or cleaning solvent.

CAUTION—The clutch throwout

bearing is permanently packed with lubricant and should not be soaked

in gasoline, as this may dissolve the lubricant from around the bearing

balls.

1. Inspect the pressure plate and flywheel for

any indication of scores on the

contact surface. Then check

the three pressure plate drive lugs for burrs. Make sure that these lugs move

freely in the three slots in

the cover. Check the clearance between the lugs and the cover; this

clearance should be from .002"

to .008".

2. Check the throwout bearing for roughness

and free fit on the sleeve of

the transmission clutch gear bearing retainer.

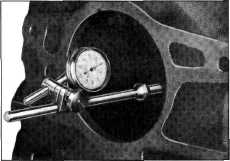

3. Check the run-out of the transmission pilot

hole in the clutch housing. Fig. 113. This should be within .008" indicator

reading. |

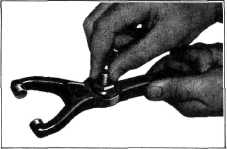

4. Check

fit of the ball in the throwout fork; this should be snug without

end-play, Fig. 114. |

||

|

|||

|

Fig. 114—Checking Free Fit of Fork Ball in Clutch

Fork

5. Inspect

the clutch disc for worn, loose or oil soaked facings, broken springs, rivets loose

in hub or "riding." Examine

the splines and check to see

that they move freely on the splines of the transmission clutch gear. If the

splines are worn, the clutch disc should be replaced.

To assure a

job that will perform smoothly and effectively for many thousands of miles,

all of the foregoing

inspections and adjustments must be made.

Clutch Disc

Two

diameter clutch discs are used in production and service. The first

or the 9-1/8" disc is used on

passenger cars and 1/2-ton trucks. The second or l0-1/4" disc is used on all 3/4

and 1-1/2-ton trucks. |

|||

|

Pilot Bearing

The clutch

pilot bearing is a cage roller type Hyatt bearing. This bearing requires

attention only when the clutch

is removed from the car, at which time it should be removed, cleaned,

inspected, and replaced if

necessary.

To remove

the bearing from the end of the crankshaft it is first necessary to remove

the bearing retainer.

Special puller, K-445, is required to remove the retainer without damaging the

roller

bearing.

This

puller is designed with a small diameter which centers into the clutch pilot bearing.

A large aligning bushing on the

puller can be moved forward and centered in the transmission pilot

hole in the clutch housing so

the retainer will be pulled straight out, and there will be no

possibility of the lip of the

retainer digging into the bore in the crankshaft. When installing this tool, the

tool head should be threaded

into the retainer two full turns and, with the clamp in position as

shown in |

|||

|

|||

|

Fig. 113-Checking Run-Out of Transmission Pilot

Hole |

|||

|

|

|||